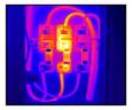

Thermography

Infrared Thermography is another nondestructive technique for detecting a variety of electrical and mechanical faults. It is a valuable tool for a complete predictive maintenance program and has been proven to reduce plant maintenance costs and improve process efficiency. Infrared Thermography can be used to:

- Check for loose or faulty electrical connections

- Excess friction in machinery and mechanical systems

- Defective steam traps

- Plugs or restrictions in process piping

- Verify process tank levels

- Check for faulty insulation or roof leaks

- Electrical overload or current imbalance

Benefits of a thorough thermographic survey include:

- Increased safety

- Improved system reliability

- Reduced unscheduled outages

- Reduced maintenance costs

- Improved efficiency and performance

- Quality assurance of new installations and repairs

We provide a detailed fault report that is easy to understand. Each report includes equipment identification, temperature readings, probable cause of each fault and recommended corrective action.