Vibration Analysis

Morgan Electric Motors provides preventive/predictive maintenance services, performed by skilled technicians. These services include: Electrical Motor Testing, Field Balancing, Thermo-graphic Surveys and Vibration Analysis of rotating machinery and Oil Analysis. Vibration Analysis provides the largest payback on a company’s investment in preventive/ predictive maintenance technologies. Machine faults can be seen before they reach a level that will cause failure. Using information about the status of a machine can help the maintenance department plan and schedule procedures, minimize downtime and increase equipment availability, greatly reducing maintenance costs. Our technicians can assist your maintenance personnel in selecting what equipment should be monitored and what technologies should be used to meet the needs of your company.

Selecting machines that have the greatest effect on productivity is an important function of a Condition Monitoring program. Machines that have a history of high maintenance costs should also be considered. Using the predictive technologies available can greatly aid the maintenance department in determining the root cause of repeated failures. Correcting the root cause will prolong machine life, provide a safer work environment and increase profitability. Experts agree that a comprehensive predictive/preventive maintenance program will combine aspects of all the programs listed. Morgan Electric Motors technicians are well qualified to provide these valuable services and help you meet your RCM goals.

Why do I need Vibration Monitoring?

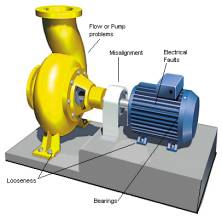

Vibration monitoring can tell us a great deal about a machine.

- Imbalance

- Misalignment

- Flow problems

- Bearing faults

- Looseness

- Electrical faults in AC and DC motors

Routine monitoring

- Tests are typically performed every 30 days. In some cases this can be extended to 90 days.

- Tests are performed at each bearing location

- Data is collected at the Horizontal, Vertical and Axial points.

Provides early warning of failure

- Trend data and predict failure

- Prevent catastrophic and secondary damage

- Reduce additional parts and repair costs

- Prevent unnecessary overtime

- Provides safer work environment

Increase profitability

- Reduce maintenance costs

- Reduce unscheduled downtime

- Reduce energy consumption

- Improve product quality

- Provide management control over downtime

What do I really Gain?

1. Equipment that fails while in use costs up to 10 times more to repair than equipment that is scheduled for repair when predicted by condition monitoring.

2. Customers can cut their annual maintenance budget by up to 33% when they convert to a maintenance program based on condition monitoring.

3. Customers can save up to 10% on energy costs by improving the efficiency of their machines.

4. Catastrophic failure can lead to unsafe working conditions or injury.

|

These types of failures can be prevented! |

What are the Key Functions?

| Detection |  |

|

|

||

| Analysis | ||

|

|

|

| Correction | ||

|

|

|

| Verify | ||

|

||

What do I need to do?

1. Determine what machines require monitoring- Equipment that has the greatest impact on production.

- Machines with high historical maintenance costs.

- Machines that would require high replacement costs.

- Typically every 30 days to provide you with good trending data.

- Can be up to 90 days, but predicting failure becomes less reliable.

- Can be more often on machines that operate in severe conditions.

- Read and understand your condition monitoring report.

- Follow the recommendations.

- Schedule the necessary repairs.

- Verify.

What will we do for you?

1. Assist you in selecting the machines- We will help you organize the list of machines so you get the best information and return on your investment.

- Provide assistance to make sure you get the reporting and trending data you want and ensure you have the information you need to make necessary repairs.

- Adjust the frequency of data collection to provide the most accurate and required information.

- Provide you with a condition monitoring report in a timely matter.

- Contact you immediately if a severe fault condition exists.

- Provide follow up monitoring to verify repairs and to provide new baseline data.